Modern trends in designing control panels – In-mold Decoration

The In-mold Decoration technology (IMD) is a modern way of decorating electronic devices, which is conducted during the process of forming plastic parts, including control panels. This solution is used in many industries and is now gaining popularity. In today’s post, I will focus on analyzing the key features of this technique and the opportunities it provides for manufacturers in the home appliance, consumer electronics, and automotive industries.

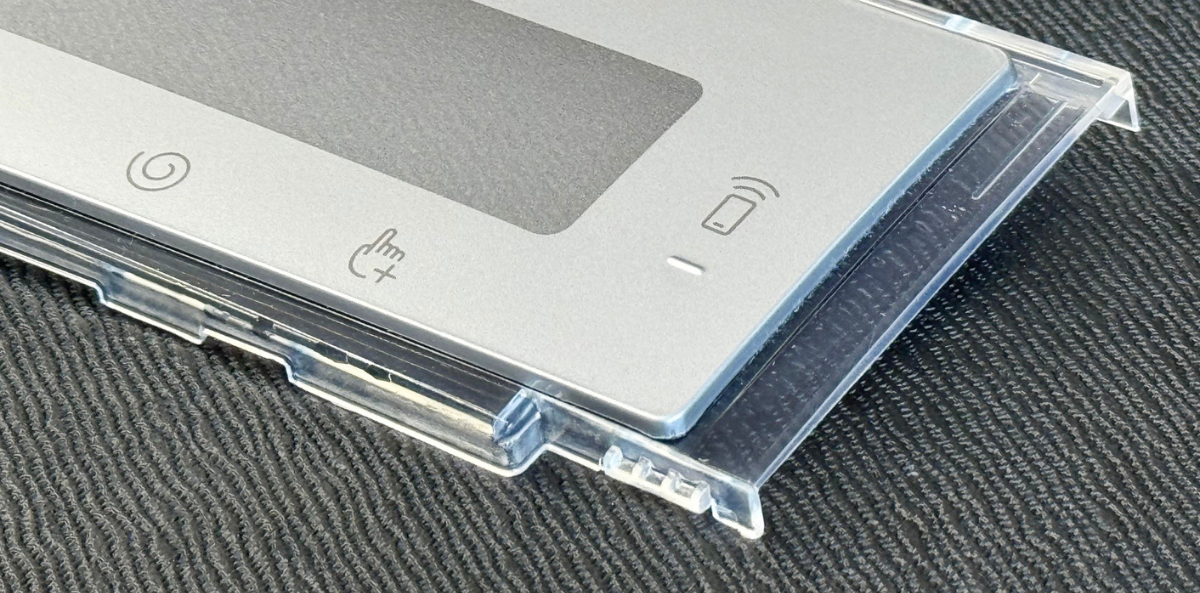

One of the major advantages of the IMD technology is the ability to create customized parts of different shapes, which are perfect as decorative or functional parts in electronic devices. At Graffiti Printing House, a member of Etisoft Group, it is a technique that supports the front panels and control panels created so far and used as control panels in the home appliance, consumer electronics and automotive industries, to name a few.

Label printing using the screen printing technique.

Aesthetics and durability of control panels thanks to the In-mold Decoration technology

With IMD, a pre-printed label using screen printing is permanently bonded with the part of the device, which affects its durability and enhances the aesthetics of the device. This eliminates the need to use external labels prone to mechanical damage to which the print is exposed during everyday use of electronic equipment.

What provides a significant advantage over classic control panels, in making parts using the In-mold Decoration technique is a considerably greater influence on the shape of the finished product. Printing directly on a plastic injection mold, although efficient and durable, is limited to flat surfaces that limit the options for designing electronic devices to some extent. With IMD, the problem disappears – the customized label is integrated with the formed part, thus expanding shape design possibilities.

Tomasz Osuch, head of the Technology Department at Graffiti Printing House

Cutting of pre-printed labels.

Applications of the IMD technique

In-mold Decoration is used in many industries, starting from small-sized electronic equipment designed for home use, to decorating sports equipment, to sophisticated medical equipment. Due to the advantages of the IMD method, i.e., print durability and flexibility in shape design, it can be used wherever both features are in demand. The products in which IMD performs well both as a decorative and functional element include:

Home appliances and consumer electronics – front panels for televisions and monitors, decoder housing components, curling irons as well as small and large home appliances such as washing machines, dryers, refrigerators, and ovens.

Automotive industry – dashboards and interior components where design is of key importance; the method of forming shapes that fit perfectly into the lines of the car is one advantage that particularly suits the needs of the automotive industry.

Sports equipment – besides the parts used mainly as functional elements, such as control panels, the IMD technology is also suitable for decorating helmets, sports goggles, and other sports accessories. In this way, non-abrasive logos or the manufacturer’s brand-related parts can be marked.

The last step is to form the panel with the printed label.

Outlook on the In-mold Decoration method

IMD is gaining popularity all over the world. With the use of screen-printed labels, the esthetics of the finished panels do not differ from those of the commonly used control panels, and the increased possibilities of forming the shape of new parts only increase the attractiveness of this technology.

Control panels – from design to finished product. How we do it?

As the technology continues to develop and market interest grows, it can be assumed that the role of products made using In-mold Decoration will only grow. It is an effective way to make electronic devices look attractive while maintaining their durability.

IMD at Etisoft Group

Graffiti Printing House, a member of Etisoft Group, draws on its expertise in screen printing to provide high-quality labels that are formed into finished plastic parts in subsequent processes. Our experienced team of experts will be happy to provide you with advice on the ideal solution tailored to the quality requirements your products need to meet.

If you are searching for aesthetic and durable panels made using the In-mold Decoration technology, then we are the right partner for you. Our experience in the field means that we not only provide printed materials but also the certainty that we will secure your supply chain for years to come.